CU+

about us

Since its creation in 1995, the company Sonico Ltd has been looking for the right direction for establishing and improving their management, production structure and policy in order to reach the level and meet the standards of a contemporary European organisation. ...history

and identity1989. In 1989

Mr. Neno Nanev started his activities with production of latchkey and other goods with the trading name "ET Key - Neno Nanev."

1992. In 1992

DB consortium Arsenal Kazanlak, Mr.Neno Nanev takes over management of Workshop 150 in the village of Rosovets. Two models of padlocks are produced there and, in 1993, a secret lock is added to the regular production.

2003. In 2003

new facilities for injection molding are installed in 2003; a machine with cold chamber casting up to 500 grams and a fully automated moulding machine casting zamac up to 350 grams.

Antimicrobial properties of copper

|

Copper – Cu Characteristics: |

|

Copper alloys: Copper + other elements (zinc, tin, nickel)

Available in various forms: sheets, strips, plates, foil, rods, preforms, etc.

|

|

Man has used the antimicrobial properties of copper since the dawn of civilization.

Besides minting coins, jewelry and weapons, ancient civilizations used copper for the treatment of wounds and for good hygiene.

- Egypt (2000 BC) - Purification of drinking water and healing of wounds

- Hippocrates (400 BC) - Treatment of leg ulcers related to varicose veins

- Aztecs - Copper oxide for skin eczemas

|

|

|

|

Scientists who have studied the natural water stored in different containers by locals from the region of Punjab (Indian rural area) established the following - after 48 hours of treatment no live bacteria remain in the copper vessels while in pottery water remains contaminated.

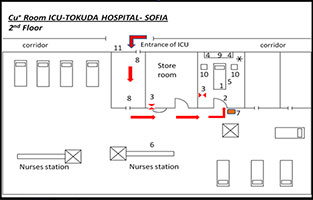

Nosocomial infections in the Republic of Bulgaria in the period 2007-2009

Nosocomial infections of 1000 discharged patients

|

University |

2007 |

2008 |

2009 |

|

Primary municipal |

11,1 |

10,9 |

10,7 |

|

Първостепенни общински |

10,8 |

9,1 |

9,3 |

|

City |

13,5 |

12,1 |

8,4 |

|

Municipal |

4,7 |

4,3 |

4,4 |

|

OG hospitals |

5,3 |

3,5 |

2,4 |

|

Specialized children |

754,1 |

704,5 |

819,2 |

|

Specialized others |

6,1 |

5,4 |

4,4 |

|

All medical institutions |

12,7 |

11,2 |

10,2 |

This information presents comparative summarized data for the spread of the nosocomial infections in the country, submitted by medical institutions for the period 2007-2009. Data are processed at the National Center for Health Information at the Ministry of Health. The most commonly reported infections in pediatric facilities are intestinal, skin, conjunctivitis, urinary infections and acute infection of the upper respiratory tract.

1. Continuously kills bacteria

2. Never wears out

3. Safe to use

|

For 4 years now laboratory tests carried out in Europe and the USA have strongly suggested that copper alloys kill 99.9% of bacteria within two hours and continue to destroy more than 99% even after repeated contamination. Moreover, the use of antimicrobial surfaces has led to 40.4% reduction in the risk of acquiring infection. |

Results of the study on the impact of antimicrobial copper properties are presented at a conference of the World Health Organization for Control and Prevention of Nosocomial Infection in Geneva on 1 July 2011

- According to several hospital surveys conducted worldwide, the copper surfaces show 90% lower level of contamination than traditional surfaces.

- Dry copper surface destroys 10 mill. bacteria for 10 minutes; their elimination on wet surface takes 45 minutes.

- Antimicrobial copper continuously kills bacteria, never wears out and is safe for use.

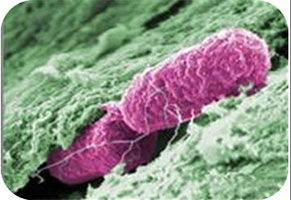

Effect of antimicrobial properties of copper on Escherichia Coli

| stainless steel | Time | Antimicrobial brass alloy |

| 31,300,000 CFUs | 0 minutes | 31,300,000 CFUs |

| 25,933,468 CFUs | 60 minutes | 2,740 CFUs |

| 21,066,000 CFUs | 120 minutes | 0 CFUs |

How does copper affect bacteria?

Each cell /incl. bacterial/ is characterized with the so called membrane voltage – the difference in the electric voltage of the external and How does copper affect the bacteria?

Each cell /incl. bacterial / is characterized with the so called membrane voltage – the difference in the electrical voltage of the exterior and interior of the cell.

In contact with the copper surface this difference is disturbed and “short circuit” appears, due to which the membrane wall weakens and makes holes.

Which microbial pathogens do kill copper?

- Adenovirus

- Candida albicans

- EscheriaColi

- HelicobacterPilori

- SalmonelaEnteritidis

- Vre

- Poliovirus

- Staphylococcus Aureus

- Influenza A

- klebsiella pneumoniae

- Pseudomonasaeruginosa

- Acinetobacterbaumannil

- Legionellapneumophila

In contact with the copper surface this difference is disturbed and “short circuit” appears, due to which the membrane wall weakens and makes holes.

How do copper ions damage the cell?

Once the outer membrane has been broken copper ions smoothly enter into the microbial cell. Copper literally suffocates the inside of the cell and impedes the cell metabolism (i.e. biochemical reactions necessary for life). The bacteria can no longer “breathe”, “eat”, or “create energy”.

Frequently Asked Questions

|

Cleaning Copper products must be cleaned in the same way as other surfaces. It is necessary to remove the dirt as it can isolate the copper surface from contact with the harmful bacteria |

|

Price

The cost of materials is a small part of the cost of the product. The lack of coverage saves costs. Copper products can be fully recycled without loss of efficiency. |

|

Safety

Copper products are safe and durable. Copper is an essential microelement in the human nutrition, along with zinc and iron. |

|

Resistance

Microorganisms die before they can reproduce, i.e. they can not evolve and develop resistance. |

|

|

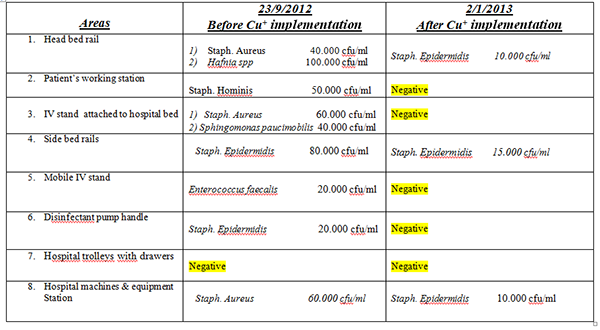

Microbiological Laboratory of the Institute of Copper in Athens

85% of touchable surfaces were replaced with antimicrobial copper. Sampling before and after project implementation Cu + in order to detect and monitor the germs and viruses.

Result: as a result of the application of antimicrobial copper surfaces. The Greek Institute of Copper reported 95% reduction of microbial pathogens. /P = 0.02, level of statistical significance/

|

|